Plastic Production Equipment

Plastic Extrusion

Extrusion Blow Moulding

Injection Stretch Blow Moulding

TECNOMATIC

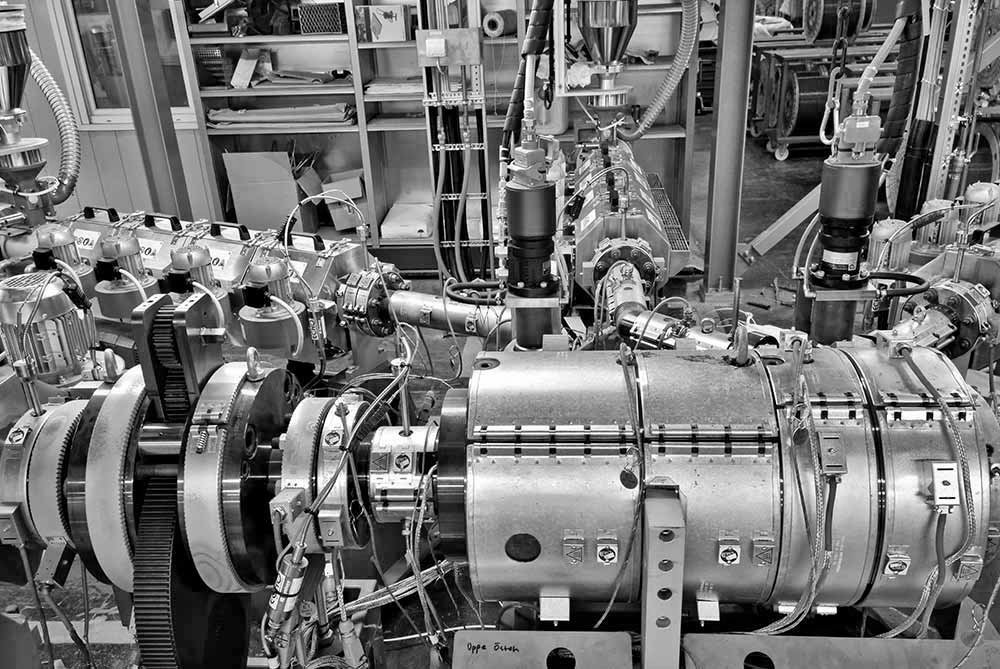

All our models are inspired by passion for extrusion and technology, which produce a wide range of extruders designed to fulfil the requirements of the pipe manufacturer, assuring high productivity and good melt omogeneity with particular care for energy and noise reduction. The high performance model ZEPHYR, in L/D 40 represents the state of the art of the gamma. Offered in gearless or traditional version the ZEPHYR series ensures outstanding performance with optimized power consumption.

Pipe Extrusion

A large selection of models and processing length for all pipe production requirements.

Extrusion Lines

Quality & performance all along the line.

SPA Magic

Magic has been in the market for the construction of Extrusion Blow Molding for plastic materials for over 60 years. Magic’s all-Electric technology is recognized by the market as the most advanced technology for processing plastic material.

Extrusion Blow Moulding

All-Electric EBM machine

The ME series has been defined by customers as "the series that the market needed". A range unique in the world, without a doubt, because for each model different versions are available to meet the customer's needs, including machines with increased stroke (LS-long stroke). It is not a result that is reached by chance, but is the result of years of research, investments, application and dedication in electrical technology. Construction carried out entirely in Italy (as for all our other machines), respecting our tradition of having solid machines, compact and reliable over time, with all the refined technological concepts dictated by the Magic experience in over 60 years of activity.

The ME series is undoubtedly unique in the world and with over 15 years of research and development in electrical technology to reach up to 55 Tons of closing force and increased strokes up to 1600 mm.

With over a dozen patents, state-of-the-art technology, intelligent and internet-connected systems, we at Magic can offer Small, Medium or Large machines depending on the request. Thanks to the precision offered by the technology (in the micrometer measurement unit) we can reach weights distributions never seen before, a stable process at each cycle, absence of contamination dictated by the machine and easy to use with the new UI between machine and operator.

Machine Benefits

-

The 3rd generation of All-Electric Blow Molding machine. Develop up to 60 Tons and 1600 mm clamping stroke.

-

Up to 65 Tons and with 30x less energy consumption and 27% more clamping force. We can develop high tonnage with very small energy requirement.

-

Up to 1600mm carriage stroke and the Long Stroke machine can offer a lot of benefits to produce a multicavity or big jerrycan container.

-

Using less energy, it can appreciate the energy savings. Use less energy for a more efficient machine.

-

Connect the machine for a fast troubleshooting and software update. Much easier and faster as never before.

-

Bigger means better. With the latest version of the magicOS it is possible to appreciate with a big screen what happen in the machine.

SPA Magic

Magic has been in the market for the construction of Extrusion Blow Molding for plastic materials for over 60 years. Magic’s all-Electric technology is recognized by the market as the most advanced technology for processing plastic material.

Injection Stretch Blow Moulding

All-Electric ISBM machine

A major step forward compared to our oldest hydraulic Biaxial series. A load of customer-focused technology, which brings many benefits, ranging from energy savings to equipment savings; in addition to the linear movements of preforms and bottles we have also the blowing station in two different phases. Equipment savings will mean one more major plus; it’s very well known that the cost of the moulds has a significant impact on the cost of the machine and it’s payback in production. Our machine will rely on the new system, patented, complete with movable mould carrier to allow the cavities of the blowing mould to be reduced by 50%.

Let’s be clearer: to blow 6 preforms, traditional technology would require 6 blowing cavities, with a clamping force of approximately 30-35 ton. With our machine we have only 3 blowing cavities and the required clamping force is reduced by 40%. Specially designed for customers who need production in limited volumes, our machine will allow them to blow simultaneously two differently shaped bottles, with an apparently similar preform and different neck.

The machine can be equipped with in line or 90° injection station. This groundbreaking project will allow the machines to be upgraded and many new details to be introduced.

Magic further proves to lead the way in flexibility and awareness.

Machine Benefits

-

The 3rd generation of All-Electric Blow Molding machine. Develop up to 60 Tons and 1600 mm clamping stroke.

-

Up to 65 Tons and with 30x less energy consumption and 27% more clamping force. We can develop high tonnage with very small energy requirement.

-

Up to 250mm opening stroke and the linear movements for preform and bottles, with electro-pneumatic movements. It is possible to produce big container up to 8lt jar.

-

Using less energy, it can appreciate the energy savings. Use less energy for a more efficient machine.

-

Connect the machine for a fast troubleshooting and software update. Much easier and faster as never before.

-

Bigger means better. With the latest version of the magicOS it is possible to appreciate with a big screen what happen in the machine.